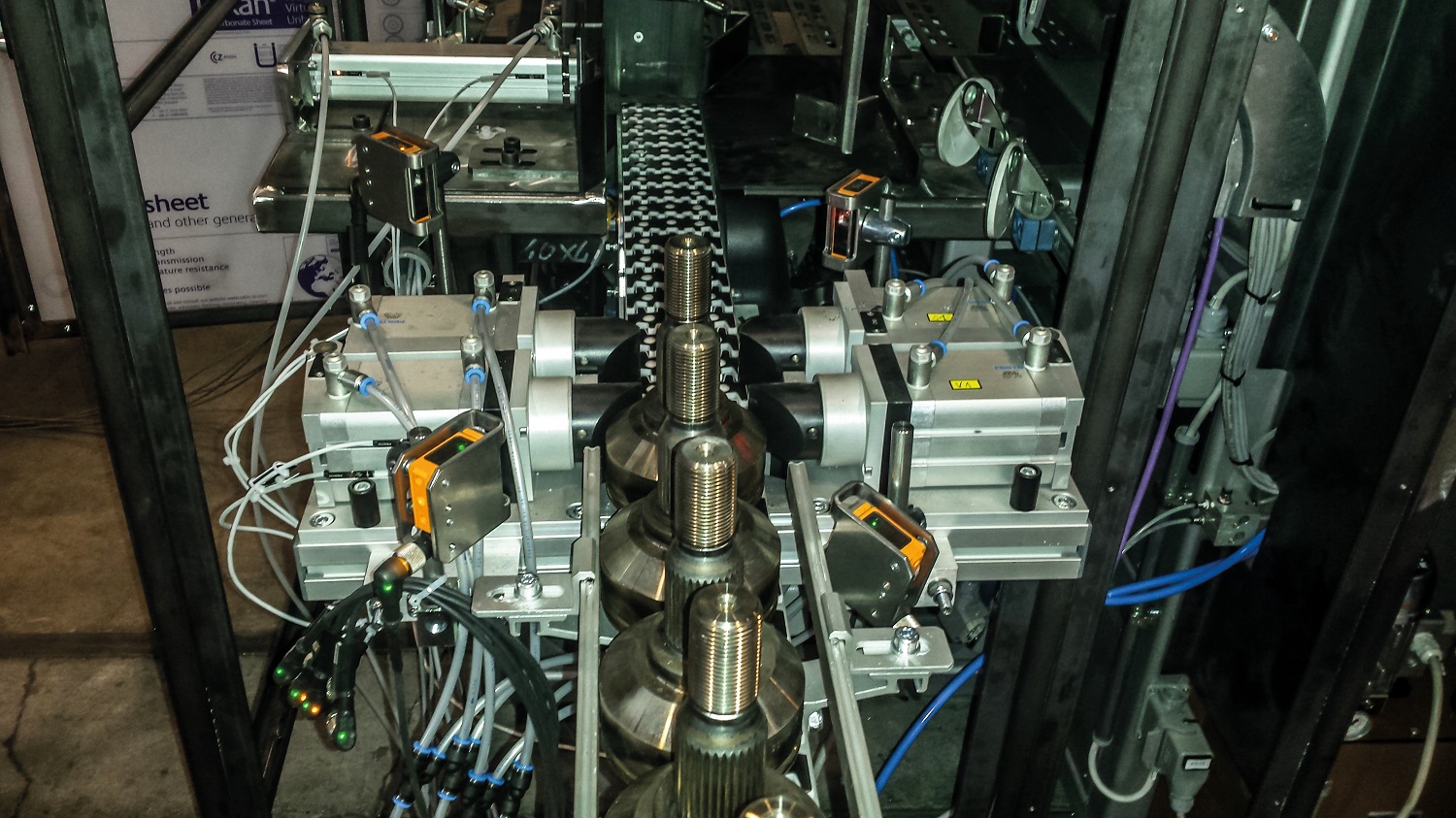

Roller Continuous Furnace # 1288

Chain conveyor electric furnace to perform heat treatment of automotive components. The furnace is composed of three different sections: heating, soaking and controlled forced cooling. High speed air circulation, optimized by CFD, assures high temperature uniformity. Air is recirculated in a chamber created between the insulated external panels and an internal stainless-steel panel. A fan mounted on the furnace floor extracts the air from the load and generates a turbulent flow in the recirculation chamber where air is heated by the heating elements. Hot air flows back into the chamber from below the parts being treated and transfers the heat to the load. The furnace is integrated in the customer’s automatic production line.

Roller Continuous Furnace # 1288

Load weight

900 Kg/h

Temperature

300 °C

Overall specifications

Width: 6.000 mm

Length: 3.300 mm

Height: 2.800 mm

Hourly production: 900 Kg/h

Max temperature: 300 °C

Temperature uniformity: +/- 5 °C