Gadda group

Making your future stronger

Who we are

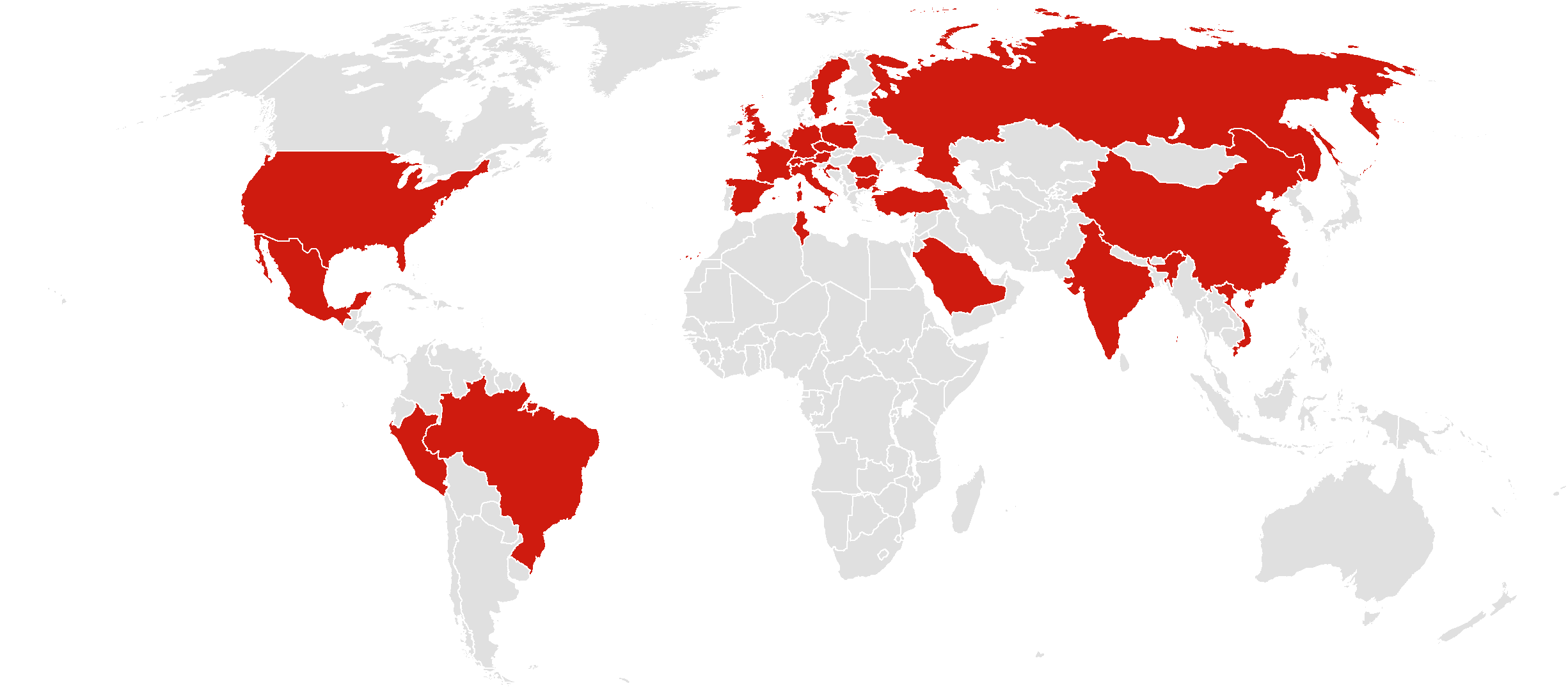

Experience and a commitment to innovation are our guiding principles. We want to be at the customer’s side with our engineers, at every step in the production cycle. From design to commissioning to support, we offer tailor-made engineering solutions with a high technology content, providing not only a product or a service, but an answer to our customers’ requirements and development opportunities. We have extensive experience, with more than 600 projects completed in Italy and around the world: we have worked for customers in Austria, Brazil, Britain, Bulgaria, China, Croatia, Czech Republic, France, Germany, India, Mexico, Peru, Poland, Romania, Russia, Saudi Arabia, Spain, Sweden, Switzerland, Tunisia, Turkey, USA, Vietnam.

Our headquarters are located in Italy: 18.000 m2 in the Canavese, one of the most industrialized areas in northern Italy, which has always been at the forefront of technology and engineering. From there, we have opened up to the world, responding to the most complex challenges, from new technologies to environmental sustainability.

For more than 40 years we have been developing, producing and installing industrial furnaces, machinery integrated heat-treatment and reheating systems.

What we do

For more than forty years, we have been developing, producing and installing industrial furnaces and machinery, integrated heat-treatment and reheating systems for ferrous and non-ferrous materials, in Italy and around the world. We are technological and strategic partners, we work with the customer at every stage of the project and in the production cycle, offering made-to-measure services and solutions in response to your needs. We are leaders in complete, direct management of every step in the engineering, commissioning and customer support cycle. An international benchmark in the metal heat treatment and reheating industry.

Why you should choose the Gadda group

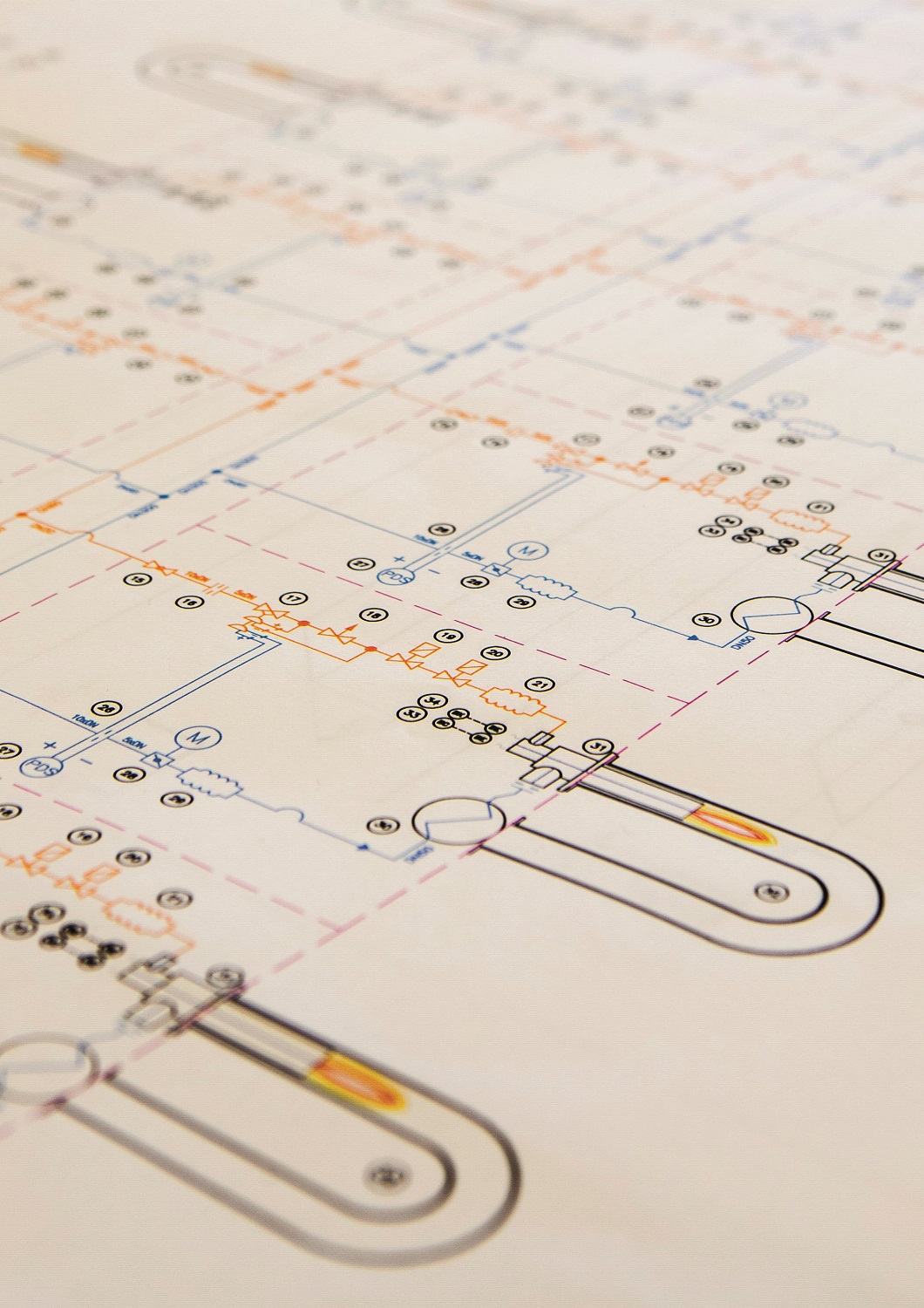

High-tech: Engineering and Innovation

The quality of our products and services has made us partners of choice in our field, providers of turnkey engineering for industry 4.0 that delivers effective, innovative, technological solutions to rationalize systems, optimize processes and costs, and consequently generate additional value. After that, we invest in our engineers to develop innovative projects that offer customers reliable, top-quality solutions to support them in the digitalization process of the so-called “fourth industrial revolution”, acting as a preferential partner to help them take advantage of opportunities for growth and development. We use thermo-fluid dynamic analysis software to research new solutions and develop and validate our projects.

An answer to our customers’ requirements and development opportunities

Tailor-made: Custom solutions

- Develop customized products to meet the specific requirements of our customers

- Provide support through each phase in the production cycle, with an all-round range of services and solutions using equipment we design, produce and test in-house.

- We are an industrial furnaces full-cycle supplier, from engineering to commissioning at the customer site.

- Provide after-sales support to guarantee the performance of our products.

- Our customer-centered approach means we focus on the customer’s specific needs at every stage in the project.

- Customer loyalty is one of our key drivers: more than 70% of our returning customers have been with us for more than 30 years.

- To date, we have offered more than 7.000 hours/year of technical support and specialist consultancy to improve the quality and

productivity of our services and products.

Made in Italy: Excellence and Quality

- We always use components of the highest quality and offer systems delivering maximum productivity levels.

- Construction and pre-assembly in Italy.

- Our systems are constructed entirely in Italy and whenever possible pre-assembled and tested at our main facility. This enables us to resolve any problems efficiently and test key product functions before shipping.

- During the construction process, customers may visit our production site to check progress.

- After pre-assembly, the product is dismantled into easily transportable parts and sent to the installation site. This significantly reduces assembly manpower hours, as well as supervision service time.

- We aim for high quality by constantly improving our products and services and developing our know-how for the growth and development of the metallurgy sector.

- The more than four hundred companies that place their trust in us are the best testimonials of the attention, commitment and level of innovation we offer today.

The more than 400 companies that place their trust in us are the best testimonials

Effective production process control & innovative eco-technologies and emissions monitoring

Sustainability: Energy Efficiency

Energy efficiency, above all, is a fundamental part of our processes, together with effective production process control, use of innovative eco-technologies and emissions monitoring.

Industries we serve