Automatic Heat Treatment Line for Forging Alloys #1389

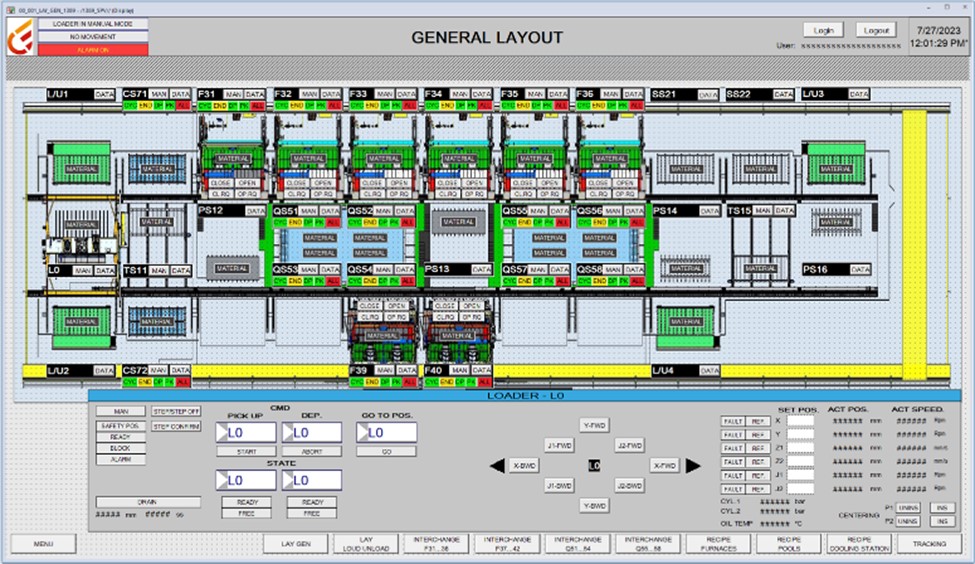

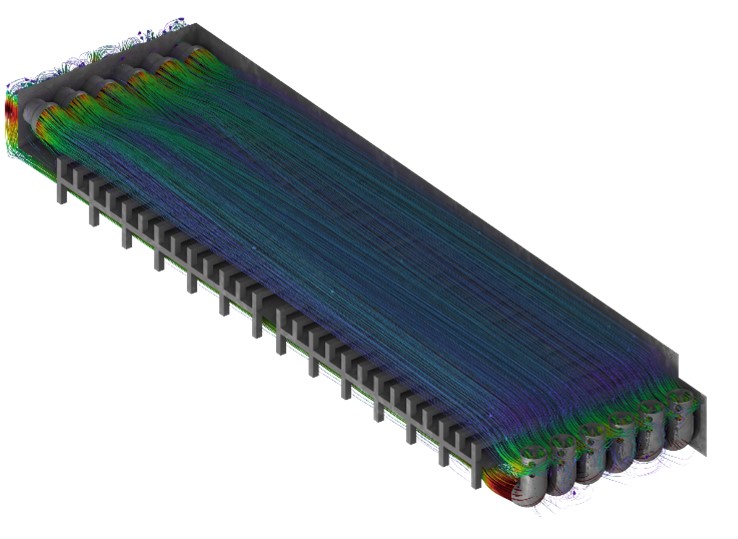

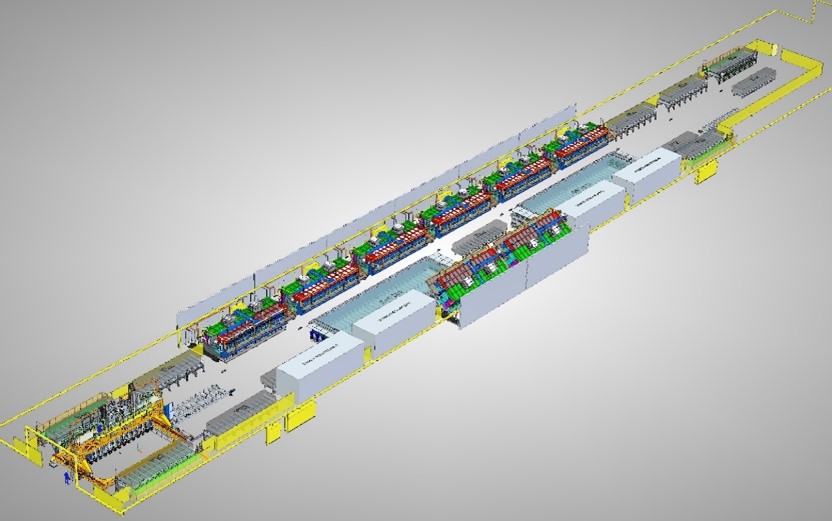

Automatic heat treatment line for forging alloys (medium and large-sized forged parts), concentrating all the possible treatments into a single island, using the flexibility of the batch furnaces together with a system that is able to manage the multitude of treatments and their combinations in a simple and straightforward manner. The overall dimensions of the entire line are 175 m x 25 m x h 9 m. Tip-up furnaces were selected to permit wide access to the loader, that serves the entire line and was designed to serve the furnaces and the deposit and cooling stations. The SCADA interface allows intuitive management for all the machines of the line. The role of the operator in the batch heat treatment line is now limited to loading and unloading the parts (in safe zones marked off by interlocked gates) and programming the recipe remotely, guaranteeing total work safety.

Automatic Heat Treatment Line for Forging Alloys #1389

Loaded weight

25 tonnes

Temperature

450°C to 1100°C

Batch line components

- 12 furnaces

- 1 cooling tank with water

- 1 quench tank with polymer

- 1 automatic loading machine

- 2 forced air cooling stations

- 2 transfer carriages

- 2 interface stations for loading and unloading

- 8 storage stations

Working zone:

- L 10.000mm

- W 2.000mm

- H 1.000mm