Batch Automatic Line #1322

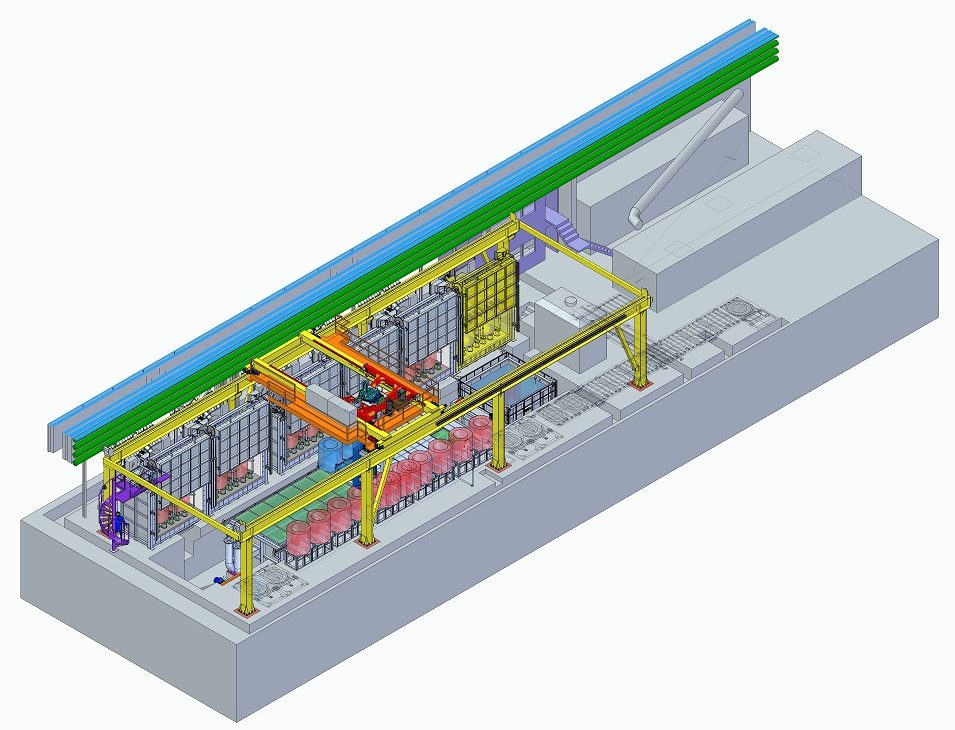

The heat treatment line is composed of 5 batch furnaces in nitrogen atmosphere with radiant tube heating elements. The line is designed to treat stainless steel wire rods and can perform various processes as: normalizing, austenitizing, annealing, solubilization, tempering, quenching in different fluids (water, polymer) and isothermal annealing with indirect air-cooling stations. The line is completely automatic with segregated working area. The load enters and exits the line through a motorized loading/unloading station. Maximum batch weight is 3 T treated up to 1.150 °C. The quenching tank has 4 Kaplan agitators and a water-cooling system, the total volume is 60 m³.

Batch Automatic Line #1322

Load weight

3.000 kg

Temperature

1.150 °C

Batch line components

– 5 chamber furnaces in nitrogen atmosphere

– 3 quenching tanks with agitators (1 water, 1 water/polymer and 1 for rinse)

– 1 automatic loader (3 T capacity)

– 1 forced cooling station

– 2 motorized loading/unloading stations

– 5 storage stations

– Custom made supervision system ready for full integration with customer management system

Load dimension

- Width: 2.800 mm

- Length: 1.300 mm

- Height: 1.100 mm

Load weight

- 3.000 Kg